Description

Tomei Valve Spring 2JZ

Tomei typically has stock available the same day. (Their factory/ warehouse is 5 minutes around the corner from us.) However, we will let you know if there are backorders or any delays. If you are looking for parts that are not on our website or want to place a bulk stock order, please contact us via the contact form.

PRODUCT INFO

| APPLICATION | COMPATIBLE LIFT(mm) | P/N | NOTES |

| 2JZ-GTE | ~10.25 | 163062 |

・OVAL CORE WIRE

・Applicable for STD base-circled camshafts & stock Outer Shim system |

FEATURE / SPEC

| DIA METER | FREE LENGTH | SET LENGTH | LIFT LENGTH |

COMPRESSED LENGTH

|

| 3.40×4.25 | 41.6mm | 34.5mm | 24.5mm | 21.5mm |

| SET LOAD | LIFT LOAD | MATERIAL | PROCESS | COLOR ID |

| 26.2±7% kgf | 72.1±7% kgf | HNK507 | Nitride | L Blue |

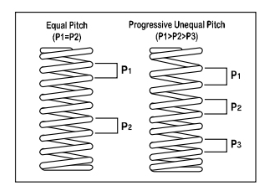

■ Multi Coil Unequal Pitch Springs

By combining several steps of spring rates into the one spring and vibration frequency becomes amazingly high. This greatly minimizes resonance and the chances of surging.

■ Advanced Oil Tempered Chromium-silicone Alloy Steel Core

Oil tempered chromium-silicone alloy steel wire is used which is considered to be the best material for springs for performance applications and evolved it even further. Combined with a new optimized design, not only did we make it tougher, we also succeeded in suppressing valve jumps or bounce even when raising the engines speeds RPM limit.

■ Shot Peening

A process that strikes many small steel balls onto the surface of the spring at high speeds is made to enhance the surface of the spring to raise its fatigue limit. Although it has been carried out earlier during the manufacturing process.

■ Warm Setting

The process that is adding higher loads beyond the actual limits to the highly heated spring. This will modify its shape and keep it permanently fixed. We succeeded in securing the highest performance over a long period of time while preventing sagging.

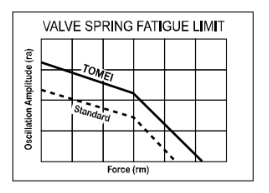

■ Nitriding

The surface treatment method for making nitrogen permeates the spring and gives it large surface compression repulsion. This method was chosen to raise the fatigue limit to suit the demands or running high lift camshafts. The dangers of spring failure is greatly reduced with the 1.5 times increase in the springs fatigue limit with the combined use of Oil tempered chromium-silicone alloy steel wire and Nitriding. This is how our valve springs are suitable for use on extreme engine speed conditions of super-high revs exceeding 10,000 RPM which had not been previously possible with high lift camshafts.

Reviews

There are no reviews yet.